In modern industrial operations, cranes are indispensable for lifting and transporting heavy loads safely and efficiently. Behind their reliable performance lies a crucial component that often goes unnoticed—the crane electrical cable. This cable not only delivers power to the crane's motors and control systems but also ensures smooth communication between different electrical components. In environments such as construction sites, shipyards, steel plants, and logistics centers, these cables must endure continuous movement, bending, and exposure to challenging conditions. A high-quality crane electrical cable is therefore fundamental for keeping cranes operational, minimizing downtime, and ensuring workplace safety.

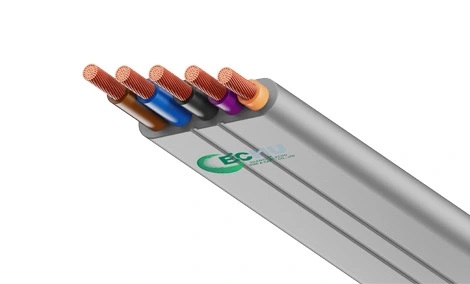

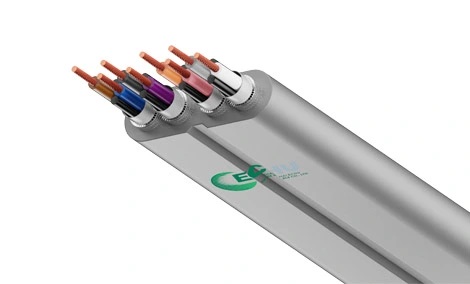

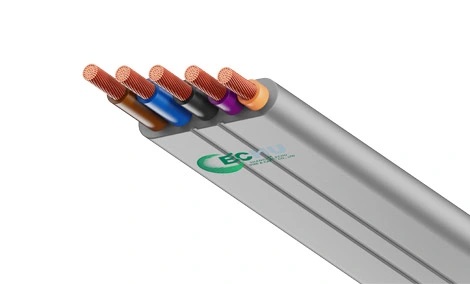

A well-designed crane electrical cable is built to withstand mechanical stress and harsh operating environments. It typically incorporates flexible copper conductors, robust insulation, and specialized sheathing materials to resist abrasion, oil, and weather exposure. Flexibility is particularly important, as crane cables must bend and move repeatedly during lifting operations without compromising performance. Heat resistance and flame-retardant properties further enhance safety by preventing potential fire hazards. At ECHU Cable, the production of crane cables adheres to strict international standards, ensuring durability and consistent quality. With over 18 years of expertise in developing specialized cables, the company has integrated advanced technologies into its manufacturing processes to meet the demanding requirements of modern cranes.

When selecting cabling solutions for cranes, it is important to distinguish the specialized crane cables from standard industrial cables. The following table outlines key differences:

Feature | Crane Electrical Cable | Standard Industrial Cable |

Flexibility | Designed for continuous bending and movement | Limited flexibility, less suitable for motion |

Mechanical Strength | Reinforced to resist abrasion and mechanical stress | Lower resistance to wear and tear |

Environmental Resistance | Resistant to oil, moisture, and outdoor conditions | Less protection in harsh environments |

Lifespan | Extended service life in dynamic applications | Shorter lifespan under constant movement |

Application Scope | Specifically for cranes, hoists, and lifting equipment | General industrial machinery and fixed systems |

This comparison highlights why crane electrical cable is a critical investment for industries that depend on heavy lifting equipment, as it combines flexibility, durability, and enhanced safety features not found in standard cables.

Founded in 2005, ECHU Cable has grown into one of China's leading one-stop suppliers of industrial cables. The company specializes in the development and production of high-performance solutions tailored to industries that demand reliability under extreme conditions. In 2010, ECHU Cable invested 100 million USD to establish its second-largest production base in Kunshan City, with a strong focus on mobile cables such as robot cables, high-flex drag chain cables, and crane electrical cables. Covering research and development, production, quality testing, warehousing, and logistics, the facility ensures every product meets ISO9001, UL, CE, and 3C standards. With its extensive experience and annual output value reaching 350 million USD, ECHU Cable has established itself as a trusted supplier for industries that rely on advanced cable technology.

As global industries expand and automation becomes more integrated into heavy-duty operations, the role of crane electrical cable will continue to grow in importance. Future designs are expected to incorporate even greater resistance to extreme temperatures, chemical exposure, and mechanical strain, while maintaining the flexibility required for continuous motion. The demand for efficiency and safety in sectors such as construction, manufacturing, shipping, and logistics will drive the development of innovative cable solutions that enhance the performance of cranes and lifting equipment. The combination of durability, reliability, and adaptability makes crane electrical cables a cornerstone of modern heavy-lifting infrastructure, ensuring that industries can operate with both confidence and efficiency.