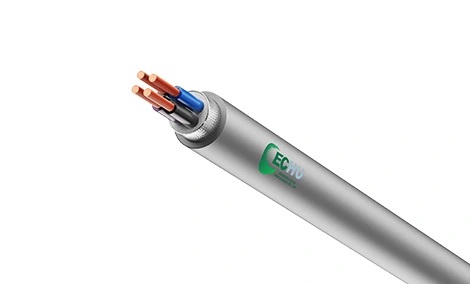

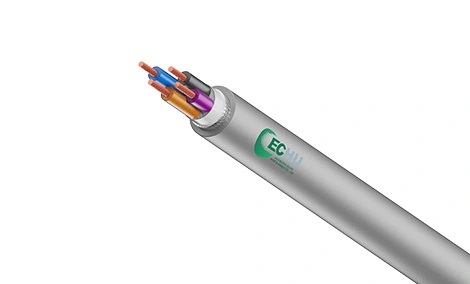

In the era of rapid industrial development, energy storage systems are playing a critical role in ensuring stability and efficiency for both renewable and conventional energy networks. A key element in these systems is the use of specialized cabling solutions that can withstand harsh conditions. Among them, the oil resistant electrical wire has become increasingly important for energy storage applications. Unlike conventional cables, oil-resistant wires are engineered to endure environments where contact with oil, lubricants, and other industrial fluids is unavoidable. Their ability to maintain performance under such conditions ensures that energy storage systems remain stable, secure, and efficient. ECHU Cable, a leading manufacturer in China, has invested in advanced production facilities to design and deliver wires that meet these exacting demands.

One of the primary benefits of oil resistant electrical wire lies in its superior insulation and sheathing materials, which prevent degradation when exposed to oil-based substances. This feature is particularly valuable in energy storage systems where cables may be used near machinery, hydraulic systems, or industrial environments with constant oil exposure. The insulation ensures long-term safety, reduces the risk of electrical faults, and extends the overall service life of the cable. At the same time, oil-resistant wires are manufactured with flexibility in mind, making them easier to install in compact or dynamic environments where space and movement are critical factors. With these characteristics, energy storage systems benefit from reduced downtime and more consistent power management.

When evaluating cabling for energy storage, it is essential to compare oil-resistant options with standard electrical cables. The following table illustrates the differences:

Feature | Oil Resistant Electrical Wire | Standard Electrical Cable |

Resistance to Oil | High, maintains performance in oily environments | Low, insulation degrades with oil contact |

Durability | Extended lifespan in industrial settings | Reduced durability in harsh conditions |

Application Scope | Suitable for energy storage, machinery, and robotics | Limited to cleaner environments |

Safety and Reliability | Enhanced insulation and protection | Higher risk of faults under oil exposure |

Flexibility | Designed for easier routing in complex systems | Often less flexible in installation |

This comparison highlights why oil resistant electrical wire is increasingly selected for advanced energy storage systems, where both reliability and longevity are vital.

Founded in 2005, ECHU Cable has specialized in the research, development, and production of advanced cables, including oil-resistant solutions. With its second major production base established in Kunshan City in 2010, the company has expanded its focus to high-performance cables for automation, robotics, and energy-related applications. By adopting international standards such as UL, CE, and 3C in its production processes, ECHU Cable ensures its Oil Resistant Electrical Wires meet global safety and performance expectations. With an annual output value reaching 350 million USD, the company has become a one-stop solution provider for industries seeking reliable and efficient cable products.

As energy storage continues to evolve alongside renewable energy technologies, the role of oil resistant electrical wire will become even more significant. Future storage systems will demand cabling solutions capable of maintaining high performance under increasingly complex conditions. Oil-resistant wires will not only safeguard against environmental challenges but also ensure that power distribution and storage remain uninterrupted. Their resilience and efficiency position them as a key enabler of next-generation energy systems, contributing to a more sustainable and reliable power infrastructure worldwide.